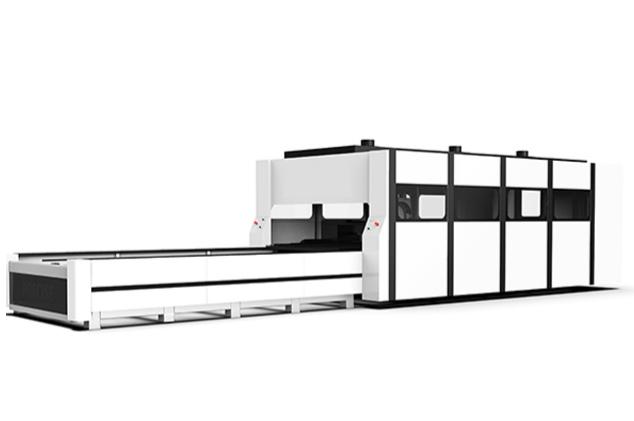

Special Price for Metal Nonmetal Laser Cutting Machine - 4KW 6KW 8KW Steel CNC Fiber Laser Cutting Machine Price – Knoppo Detail:

Video

Application

Applicable Materials Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine can cut thick stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate.

Applicable Industries Of CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine is used for industry of machinery parts, electrics, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts, metal jewelry and other metal cutting fields.

Sample

Configuration

* Japan SMC Electric Proportional Valve.

*Positioning and re-positioning accuracy is 0.02mm.

* IPG , Raycus or Max laser source in 4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW, 30KW – Lifespan 100,000 hours.

* Precision German PRECITEC auto focus laser head.

* Ball screw drive guide rail system.

* German Rexroth Motor Driver.

*German Rexroth guide rails.

* German Schneider Electronics Parts.

* German BECKOFF software including nesting capability – stable and efficient productivity.

* Water chiller and extraction system included.

Techinical parameters

|

Model |

KP6020 |

|

Wavelength |

1070nm |

|

Cutting Area |

3000*1500mm, 4000*2000mm, 6000*2000mm, 6000*2500mm. |

|

Laser Power |

4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW,30KW |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting parameters

|

4000W |

6000W |

8000W |

12000W |

15000W |

||

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8–10 |

8–10 |

8–10 |

9–11 |

9–11 |

|

2 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

5–7.5 |

|

|

3 |

3.5–5.0 |

3.5–5 |

3.5–5 |

3.5–5.5 |

3.5–5.5 |

|

|

4 |

3.0–4.0 |

3.0–4.5 |

3.0–4.5 |

3.5–5 |

3.5–5 |

|

|

5 |

2.7–3.6 |

3.0–4.2 |

3.0–4.2 |

3.3–4.8 |

3.3–4.8 |

|

|

6 |

2.5–3.4 |

2.5–3.5 |

2.6–3.7 |

3.0–4.2 |

3.0–4.2 |

|

|

8 |

2.0–3.0 |

2.2–3.2 |

2.3–3.5 |

2.5–3.5 |

2.5–3.5 |

|

|

10 |

1.5–2.4 |

1.8–2.5 |

2–2.5 |

2.2–2.7 |

2.2–2.7 |

|

|

12 |

1.2–1.8 |

1.2–2.0 |

1.2–2.1 |

1.2–2.1 |

1.2–2.1 |

|

|

14 |

0.9–1.2 |

1.2–1.8 |

1.2–1.9 |

1.7–1.9 |

1.5–1.9 |

|

|

16 |

0.8–1.0 |

0.8–1.3 |

0.8–1.5 |

1.2–1.7 |

1.2–1.7 |

|

|

18 |

0.6–0.9 |

0.6–0.9 |

0.8–1.5 |

1.0–1.8 |

1.2–1.5 |

|

|

20 |

0.5–0.8 |

0.5–0.8 |

0.6–1.3 |

0.6–1.5 |

1.2–1.5 |

|

|

22 |

0.4–0.8 |

0.4–0.8 |

0.5–0.8 |

0.5–1.5 |

1.0–1.5 |

|

|

25 |

|

0.3–0.55 |

0.3–0.7 |

0.5–1.1 |

0.8–1.5 |

|

|

30 |

|

|

0.2–0.7 |

0.3–0.9 |

0.6–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

40 |

|

|

|

0.2–0.4 |

0.3–0.5 |

|

|

45 |

|

|

|

|

0.2–0.5 |

|

|

50 |

|

|

|

|

0.1–0.5 |

|

|

Stainless steel |

1 |

32–45 |

42–52 |

50–65 |

70–85 |

72–100 |

|

2 |

16–28 |

20–33 |

30–40 |

40–66 |

45–70 |

|

|

3 |

7.0–15 |

15–22 |

18–27 |

35–45 |

38–50 |

|

|

4 |

5.0–8.0 |

10–15 |

12–16 |

20–32 |

25–35 |

|

|

5 |

3.5–5.0 |

8.0–12 |

10–15 |

18–25 |

20–30 |

|

|

6 |

2.5–4.5 |

4.8–8.0 |

6.0–10.0 |

12–15 |

15.0–25.0 |

|

|

8 |

1.2–2.0 |

3.0–4.0 |

3.5–5.0 |

8–12 |

8.0–12.0 |

|

|

10 |

0.8–1.2 |

1.6–2.5 |

2.0–2.7 |

6.0–8.0 |

6.0–10.0 |

|

|

12 |

0.5–0.8 |

0.8–1.5 |

1.2–2.0 |

4.0–5.5 |

4.0–6.0 |

|

|

14 |

0.4–0.6 |

0.6–0.8 |

1.2–1.8 |

3.0–5.0 |

3.5–6.0 |

|

|

16 |

|

0.5–0.8 |

1.0–1.6 |

2.2–2.8 |

2.5–3.0 |

|

|

18 |

|

0.4–0.6 |

0.8–1.2 |

1.2–2.0 |

1.2–2.2 |

|

|

20 |

|

0.3–0.5 |

0.4–0.7 |

1.0–1.6 |

1.3–1.8 |

|

|

25 |

|

0.2–0.4 |

0.3–0.5 |

0.5–0.8 |

0.6–1.2 |

|

|

30 |

|

|

0.2–0.4 |

0.3–0.6 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.5 |

0.4–0.8 |

|

|

40 |

|

|

|

0.3–0.5 |

0.3–0.6 |

|

|

45 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.1–0.5 |

|

|

60 |

|

|

|

|

0.1-0.2 |

|

|

70 |

|

|

|

|

0.05–0.1 |

|

|

Aluminum |

1 |

35–45 |

42–55 |

48–65 |

60–85 |

70–100 |

|

2 |

13–24 |

20–40 |

25–48 |

38–50 |

40–55 |

|

|

3 |

7.0–13 |

15–25 |

20–33 |

30–40 |

35–45 |

|

|

4 |

4.0–5.5 |

9.5–12 |

13–18 |

20–30 |

30–40 |

|

|

5 |

3.0–4.5 |

5.0–8.0 |

9.0–12 |

15–25 |

20–30 |

|

|

6 |

2.0–3.5 |

3.8–5.0 |

4.5–8.0 |

10–15 |

15–24 |

|

|

8 |

0.9–1.6 |

2.0–2.5 |

4.0–5.5 |

7.0–12 |

8.0–12.0 |

|

|

10 |

0.6–1.2 |

1.0–1.5 |

2.2–3.0 |

4.5–8.0 |

6.0–10.0 |

|

|

12 |

0.4–0.6 |

0.8–1.0 |

1.5–1.8 |

4.0–5.0 |

4.0–6.0 |

|

|

16 |

0.3–0.4 |

0.5–0.8 |

1.0–1.6 |

1.5–2.5 |

2.0–3.0 |

|

|

20 |

|

0.5–0.7 |

0.7–1.0 |

0.9–1.5 |

1.3–1.8 |

|

|

25 |

|

0.3–0.5 |

0.4–0.7 |

0.6–0.9 |

0.6–1.2 |

|

|

30 |

|

|

0.3–0.6 |

0.3–0.8 |

0.5–1.0 |

|

|

35 |

|

|

|

0.3–0.6 |

0.3–0.8 |

|

|

40 |

|

|

|

0.2–0.4 |

0.2–0.5 |

|

|

50 |

|

|

|

0.1–0.2 |

0.3–0.7 |

|

|

60 |

|

|

|

|

0.2–0.5 |

|

|

Brass |

1 |

25–35 |

35–45 |

40–55 |

55–65 |

75–85 |

|

2 |

8.0–12 |

20–30 |

28–40 |

38–50 |

40–55 |

|

|

3 |

5.0–8.0 |

12–18 |

20–30 |

20–30 |

32–50 |

|

|

4 |

3.2–5.5 |

5.0–8.0 |

10–15 |

15–20 |

27–35 |

|

|

5 |

2.0–3.0 |

4.5–6.0 |

6.0–9.0 |

10–15 |

18–26 |

|

|

6 |

1.4–2.0 |

3.0–4.5 |

4.5–6.5 |

6.0–8.0 |

10–18 |

|

|

8 |

0.7–1.2 |

1.6–2.2 |

2.4–4.0 |

5.0–7.0 |

8.0–10.0 |

|

|

10 |

0.2–0.5 |

0.8–1.2 |

1.5–2.2 |

4.5–6.5 |

5.0–7.0 |

|

|

12 |

|

0.3–0.5 |

0.8–1.2 |

2.4–4.0 |

2.8–4.2 |

|

|

14 |

|

0.3–0.4 |

0.4–0.6 |

0.8–1.5 |

1.0–1.8 |

|

|

16 |

|

|

0.3–0.5 |

0.6–1.2 |

0.8–1.5 |

|

|

18 |

|

|

|

0.4–0.6 |

0.6–0.8 |

|

|

20 |

|

|

|

0.3–0.5 |

0.4–0.6 |

|

|

25 |

|

|

|

|

0.3–0.5 |

|

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Special Price for Metal Nonmetal Laser Cutting Machine - 4KW 6KW 8KW Steel CNC Fiber Laser Cutting Machine Price – Knoppo, The product will supply to all over the world, such as: Chile, Croatia, Bolivia, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

-

Professional China Cnc Shearing Machine - QC11...

-

Best Price for Wood Co2 Laser Marker - KML-FC ...

-

Cheap PriceList for Plywood Co2 Laser Engraver ...

-

Factory Free sample Wood Co2 Laser Engraving Cu...

-

New Arrival China Mild Steel Fiber Laser Cuttin...

-

Chinese Professional Stainless Steel Fiber Lase...