To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for OEM Manufacturer China Laser Machine Manufacturer Laser Cleaning Machine for Rust Paint Oil Welding Spot, Our ultimate target is usually to rank as a top brand also to lead as a pioneer in our field. We are sure our profitable experience in tool generation will gain customer’s trust, Wish to co-operate and co-create a far better foreseeable future with you!

To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for China 100W Portable Laser Cleaner, Tire Mold Cleaner, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don’t hesitate to contact us. We will do our best to meet your needs.

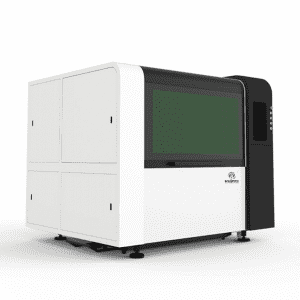

Laser Source And Water Chiller

Features

Laser is recongnized to be an ideal heat source for welding, and high technology. Laser welding has the advantages of concentrated heating, less heat input, small deformation, and fast welding speed; the depth ratio of the weld is large, the weld is flat and beautiful, no treatment or simple treatment is required after welding, the quality of the weld is good, and there is no air hole; it can be accurately controlled , The focused light spot is small, the positioning accuracy is high, and it is easy to realize automation; it is not only suitable for conventional materials, but also particularly suitable for insoluble metals and heat-resistant alloys. Titanium alloys have dissimilar metals with large differences in thermal physical properties, workpieces with large differences in volume and thickness, and components near the weld that are flammable, cracked, and explosive.

Compared with vacuum electron beam welding, laser welding has the advantages of no X-ray generation, no vacuum chamber, and unlimited workpiece volume. Laser welding can be used as the final processing, and the weld seam is beautiful . In many cases, the weld seam can be as strong as the base material. Laser welding can be spot welding, continuous seam welding, stitch welding, sealed welding, etc., with high aspect ratio, small weld width, small heat-affected zone and small deformation.

Sample

Techinical parameters

|

Model |

KW-M |

|

Wavelength |

1070nm |

|

Cable Length |

10m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W |

|

Cooling Type |

Water Chiller |

|

Laser Source |

Fiber Laser |

|

Dimension |

1230*600*1200mm |

|

Weight |

300kg |

Advantages

1 . The operation is simple, unexperienced people can also use it quickly.

2. The welding speed is super fast. A handheld laser welding machine can replace the output of 3 to 5 welders.

3 . Welding is without consumables, saving costs in production.

4 . After the welding is completed, the welding seam is smooth and white, without polishing.

5. The laser welding machine has concentrated energy, small heat reflection range, and the product is not easy to deform.

6. The laser welding machine has concentrated energy, and the welding intensity is very high.

7. The energy and power of the laser welding machine are digitally controlled, which can meet various welding requirements, such as complete penetration, penetration, spot welding, and so on.

Video

To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for OEM Manufacturer China Laser Machine Manufacturer Laser Cleaning Machine for Rust Paint Oil Welding Spot, Our ultimate target is usually to rank as a top brand also to lead as a pioneer in our field. We are sure our profitable experience in tool generation will gain customer’s trust, Wish to co-operate and co-create a far better foreseeable future with you!

OEM Manufacturer China 100W Portable Laser Cleaner, Tire Mold Cleaner, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don’t hesitate to contact us. We will do our best to meet your needs.

-

Good User Reputation for China High Efficiency ...

-

Trending Products China Cheap High Quality CNC ...

-

Short Lead Time for China Flexible Beam CNC Pla...

-

Professional Factory for China Monthly Deals Th...

-

Factory Cheap Hot China Exchange Platform Fiber...

-

100% Original China H Beam Plasma Cutting Machi...