Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of New Fashion Design for China Factory 1000W 2000W 3000W 6000W CNC Laser Cutter Fiber Laser Cutting Machine for Sheet Metal Steel, The mission of our company would be to present the very best high quality solutions with greatest rate. We’ve been seeking ahead to doing business along with you!

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of China Steel Cutting, laser cutter, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

Video

Features

1. Excellent beam quality: smaller spot size, higher work efficiency and better processing quality;

2. Fast cutting speed: about twice the cutting speed of CO2 laser machine or plasma cutting machine ;

3. High performance : the stable performance was acquired through the application of world’s top fiber laser source which makes it possible to cut at any point with equal quality through fiber transmission.

4. High electrical conversion efficiency: fiber laser cutting machine has 3 times higher electro-optical conversion efficiency than CO2 laser cutting machine, saving energy and protecting environment.

5. Low maintenance cost: fiber transmission without using reflective lenses saves a lot of time in optical path adjustment and achieves maintenance-free results.

Techinical parameters

|

Model |

KF3015 , KF4020 , KF6015 , KF6020 ,KF6025 |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W / 6000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

|

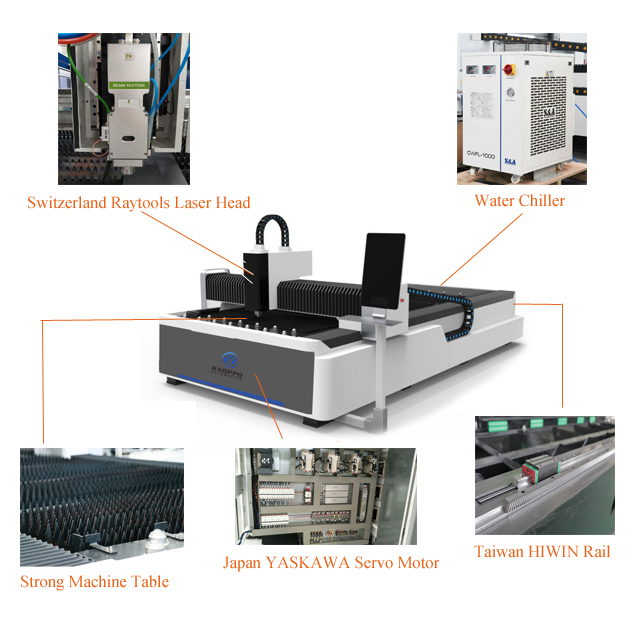

Laser Head |

Switzerland Raytools |

|

Laser Source |

Raycus / MAX / IPG |

|

System |

CYPCUT |

|

Servo Motor |

Japan Yaskawa |

|

Servo Driver |

Japan Yaskawa |

|

Water Chiller |

S&A |

Cutting parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

|

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|

|

18 |

|

|

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|

|

20 |

|

|

|

0.5–0.8 |

0.5–0.8 |

|

|

22 |

|

|

|

0.3–0.7 |

0.4–0.8 |

|

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

|

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|

|

10 |

|

|

|

0.6–0.8 |

0.8–1.2 |

|

|

12 |

|

|

|

0.4–0.6 |

0.5–0.8 |

|

|

14 |

|

|

|

|

0.4–0.6 |

|

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

|

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

|

|

5 |

|

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

|

|

6 |

|

|

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|

|

8 |

|

|

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|

|

10 |

|

|

|

0.4–0.7 |

0.6–1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4–0.6 |

|

|

16 |

|

|

|

|

0.3–0.4 |

|

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

|

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

|

|

5 |

|

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

|

|

6 |

|

|

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|

|

8 |

|

|

|

0.5–0.7 |

0.7–1.2 |

|

|

10 |

|

|

|

|

0.2–0.5 |

|

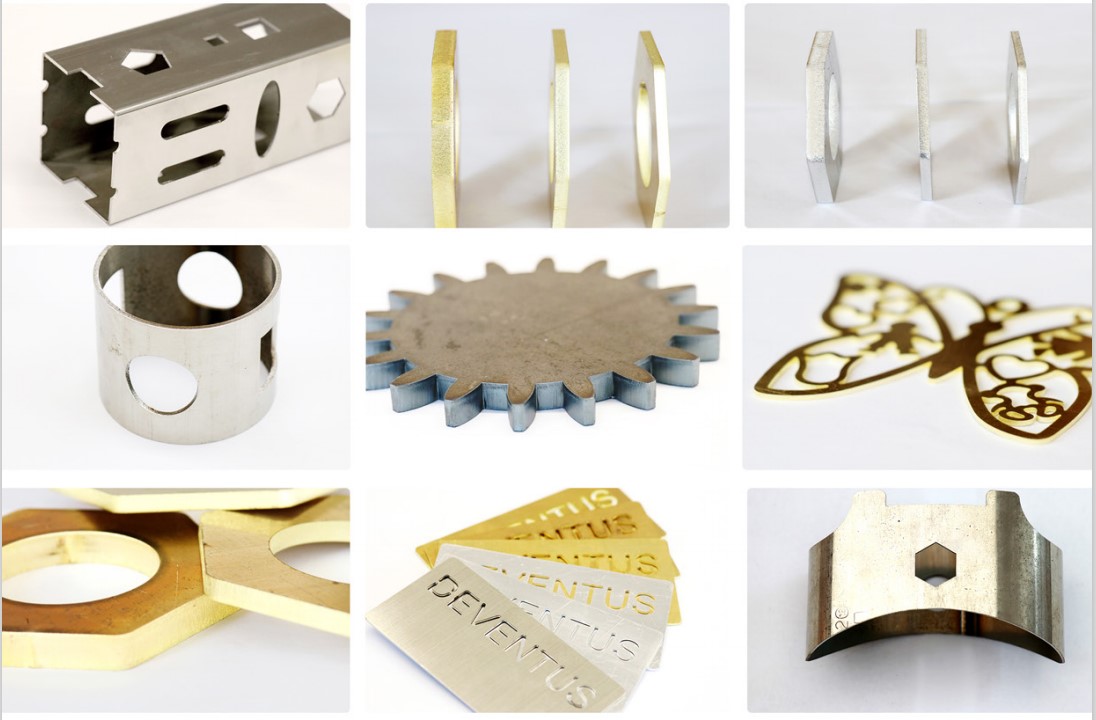

Sample

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of New Fashion Design for China Factory 1000W 2000W 3000W 6000W CNC Laser Cutter Fiber Laser Cutting Machine for Sheet Metal Steel, The mission of our company would be to present the very best high quality solutions with greatest rate. We’ve been seeking ahead to doing business along with you!

New Fashion Design for China Steel Cutting, Laser Cutter, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

-

Low MOQ for China Small Name Plate Jewelry Ster...

-

New Delivery for 2021 Newest China Factory 1000...

-

factory Outlets for China Manufacture Fiber Opt...

-

Competitive Price for China Fortune Laser 1000W...

-

High definition China Auto Focus 2kw 3kw 4kw Fi...

-

Factory source China Acrylic Name Plate Laser C...