Manufactur standard Copper Laser Cutter - Dual Used Metal Pipe And Plate Fiber Laser Cutter 2000W 3000W 4000W 6000W – Knoppo Detail:

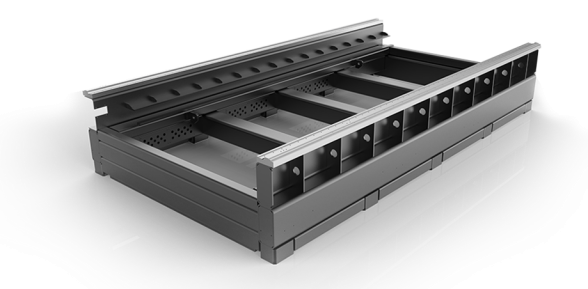

Main Features of KF-T Series dual used fiber laser cutter:

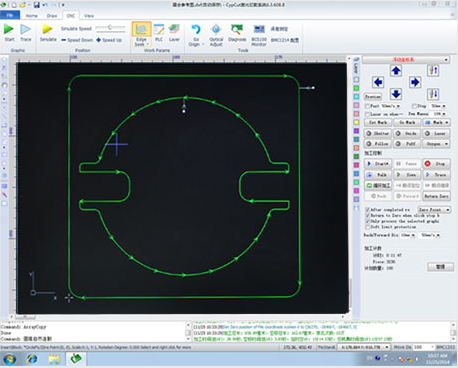

1. BETTER CUTTING QUALITY

Laser has a narrower kerf, meaning less material is wasted. More than this, laser cutting requires less manpower and even no secondary processing for most parts.

2.HIGHER CUTTING PRECISION

Laser cutting, 0.14mm; Plasma cutting, 0.4mm And at the vertical cross, laser cutting has a smaller bevel angle than plasma cutting.

3. LOWER CUTTING COSTS

Getting rid of secondary finishing, with smoother cutting surface, less dross, and smaller deformation.

4. FASTER CUTTING SPEED

Laser cutting speed can reach up to three times faster than plasma cutting.

5. ENVIRONMENT-FRIENDLY PROCESSING

Fiber laser cutting machine is cleaner and more environment-friendly than the smoky and noisy plasma cutting.

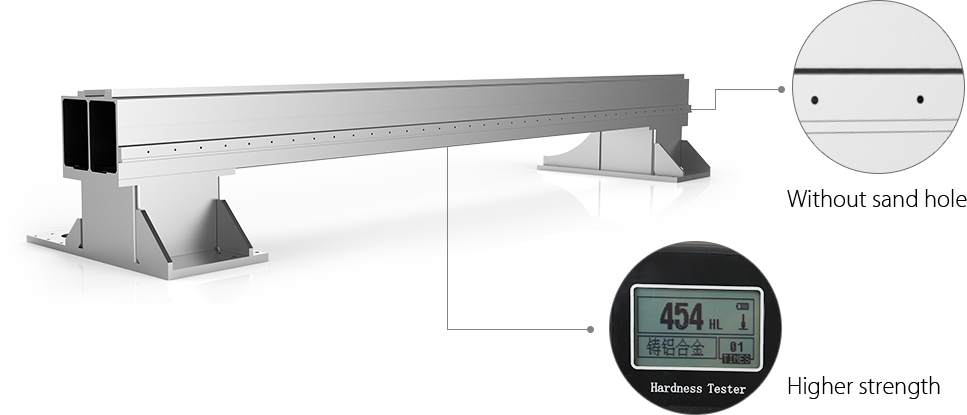

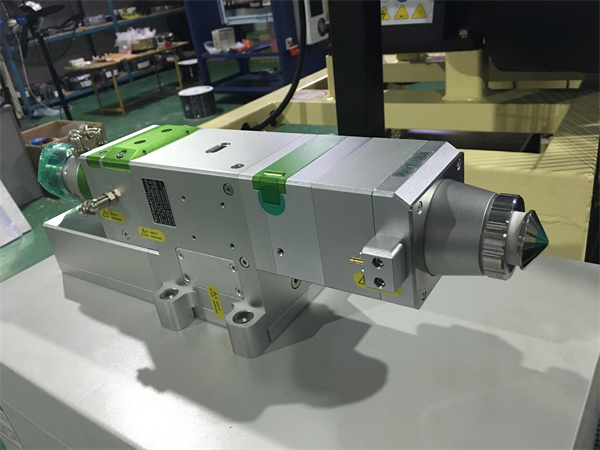

Configuration :

Techinical Parameters

|

Model |

KF-TSeries |

|

Wavelength |

1070nm |

|

Sheet Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W /6000W /8000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting Parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

4000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0–10 |

15–26 |

24–32 |

30–40 |

33–43 |

|

2 |

4.0–6.5 |

4.5–6.5 |

4.7–6.5 |

4.8–7.5 |

15–25 |

|

|

3 |

2.4–3.0 |

2.6–4.0 |

3.0–4.8 |

3.3–5.0 |

7.0–12 |

|

|

4 |

2.0–2.4 |

2.5–3.0 |

2.8–3.5 |

3.0–4.2 |

3.0–4.0 |

|

|

5 |

1.5–2.0 |

2.0–2.5 |

2.2–3.0 |

2.6–3.5 |

2.7–3.6 |

|

|

6 |

1.4–1.6 |

1.6–2.2 |

1.8–2.6 |

2.3–3.2 |

2.5–3.4 |

|

|

8 |

0.8–1.2 |

1.0–1.4 |

1.2–1.8 |

1.8–2.6 |

2.0–3.0 |

|

|

10 |

0.6–1.0 |

0.8–1.1 |

1.1–1.3 |

1.2–2.0 |

1.5–2.4 |

|

|

12 |

0.5–0.8 |

0.7–1.0 |

0.9–1.2 |

1.0–1.6 |

1.2–1.8 |

|

|

14 |

0.5–0.7 |

0.8–1.0 |

0.9–1.4 |

0.9–1.2 |

||

|

16 |

0.6-0.8 |

0.7–1.0 |

0.8–1.0 |

|||

|

18 |

0.5–0.7 |

0.6–0.8 |

0.6–0.9 |

|||

|

20 |

0.5–0.8 |

0.5–0.8 |

||||

|

22 |

0.3–0.7 |

0.4–0.8 |

||||

|

Stainless steel |

1 |

18–25 |

20–27 |

24–50 |

30–35 |

32–45 |

|

2 |

5–7.5 |

8.0–12 |

9.0–15 |

13–21 |

16–28 |

|

|

3 |

1.8–2.5 |

3.0–5.0 |

4.8–7.5 |

6.0–10 |

7.0–15 |

|

|

4 |

1.2–1.3 |

1.5–2.4 |

3.2–4.5 |

4.0–6.0 |

5.0–8.0 |

|

|

5 |

0.6–0.7 |

0.7–1.3 |

2.0-2.8 |

3.0–5.0 |

3.5–5.0 |

|

|

6 |

0.7–1.0 |

1.2-2.0 |

2.0–4.0 |

2.5–4.5 |

||

|

8 |

0.7-1.0 |

1.5–2.0 |

1.2–2.0 |

|||

|

10 |

0.6–0.8 |

0.8–1.2 |

||||

|

12 |

0.4–0.6 |

0.5–0.8 |

||||

|

14 |

0.4–0.6 |

|||||

|

Aluminum |

1 |

6.0–10 |

10–20 |

20–30 |

25–38 |

35–45 |

|

2 |

2.8–3.6 |

5.0–7.0 |

10–15 |

10–18 |

13–24 |

|

|

3 |

0.7–1.5 |

2.0–4.0 |

5.0–7.0 |

6.5–8.0 |

7.0–13 |

|

|

4 |

1.0–1.5 |

3.5–5.0 |

3.5–5.0 |

4.0–5.5 |

||

|

5 |

0.7–1.0 |

1.8–2.5 |

2.5–3.5 |

3.0–4.5 |

||

|

6 |

1.0–1.5 |

1.5–2.5 |

2.0–3.5 |

|||

|

8 |

0.6–0.8 |

0.7–1.0 |

0.9–1.6 |

|||

|

10 |

0.4–0.7 |

0.6–1.2 |

||||

|

12 |

0.3-0.45 |

0.4–0.6 |

||||

|

16 |

0.3–0.4 |

|||||

|

Brass |

1 |

6.0–10 |

8.0–13 |

12–18 |

20–35 |

25–35 |

|

2 |

2.8–3.6 |

3.0–4.5 |

6.0–8.5 |

6.0–10 |

8.0–12 |

|

|

3 |

0.5–1.0 |

1.5–2.5 |

2.5–4.0 |

4.0–6.0 |

5.0–8.0 |

|

|

4 |

1.0–1.6 |

1.5–2.0 |

3.0-5.0 |

3.2–5.5 |

||

|

5 |

0.5–0.7 |

0.9–1.2 |

1.5–2.0 |

2.0–3.0 |

||

|

6 |

0.4–0.9 |

1.0–1.8 |

1.4–2.0 |

|||

|

8 |

0.5–0.7 |

0.7–1.2 |

||||

|

10 |

0.2–0.5 |

|||||

video

Product detail pictures:

Related Product Guide:

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for Manufactur standard Copper Laser Cutter - Dual Used Metal Pipe And Plate Fiber Laser Cutter 2000W 3000W 4000W 6000W – Knoppo, The product will supply to all over the world, such as: Uruguay, Ghana, Juventus, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

-

Free sample for Round Pipe Cutting Machine - R...

-

Wholesale Laser Engraving - Small Portable Woo...

-

OEM/ODM Supplier Metal Engraver - 1390 Metal A...

-

Factory Outlets Metal Nonmetal Co2 Laser Cuttin...

-

Hot New Products Laser Equipment - 4KW 6KW 8KW...

-

China New Product 1000w Fiber Laser Cutting Mac...