Application

Application Of Fiber laser Cleaning Machine

1. Mold industry

The laser can make the non-contact cleaning of the mold, which is very safe for the surface of the mold, can ensure its accuracy, and can clean the sub-micron dirt particles that cannot be removed by traditional cleaning methods, so as to achieve truly pollution-free, efficient and high-quality cleaning.

2. Precision instrument industry

The precision machinery industry often needs to remove esters and mineral oils used for lubrication and corrosion resistance from parts, usually chemically, and chemical cleaning often leaves residues. Laser deesterification can completely remove esters and mineral oils without damaging the surface of the parts. The laser promotes the explosive gasification of the thin oxide layer on the surface of the part to form a shock wave, which results in the removal of contaminants rather than mechanical interaction.

3. Rail industry

At present, all the pre-welding cleaning of rails adopts grinding wheel and abrasive belt grinding type cleaning, which causes serious damage to the substrate and serious residual stress, and consumes a lot of grinding wheel consumables every year, which is costly and causes serious dust pollution to the environment. Laser cleaning can provide high-quality and efficient green cleaning technology for my country's high-speed railway track laying production, solve the above problems, eliminate welding defects such as seamless rail holes and gray spots, and improve the stability and safety of my country's high-speed railway operation.

4. Aviation industry

The surface of the aircraft needs to be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. Chemical immersion/wiping is the main paint stripping method in the aviation field. This method results in a large amount of chemical auxiliary waste, and it is impossible to achieve local maintenance and paint stripping. This process is heavy workload and harmful to health. Laser cleaning enables high-quality removal of paint on aircraft skin surfaces and is easily automated for production. At present, this technology has been applied to the maintenance of some high-end models abroad.

5. Shipbuilding industry

At present, the pre-production cleaning of ships mainly adopts the sand blasting method. The sand blasting method has caused serious dust pollution to the surrounding environment and has been gradually banned, resulting in the reduction or even suspension of production by ship manufacturers. Laser cleaning technology will provide a green and pollution-free cleaning solution for anti-corrosion spraying on ship surfaces.

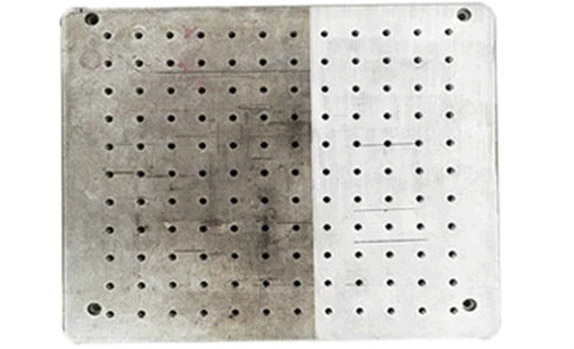

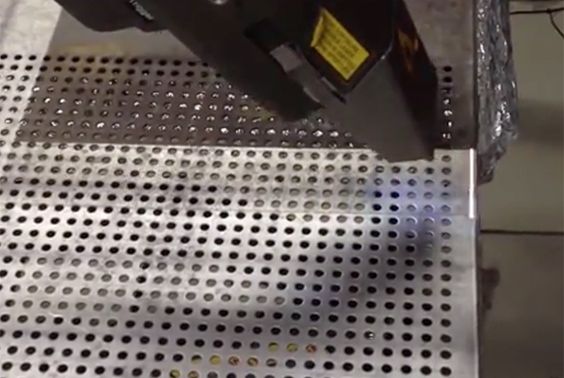

Sample

Techinical parameters

| NO | Description | Parameter |

| 1 | Model | KC-M |

| 2 | Laser Power | 1000W 1500W 2000W 3000W |

| 3 | Laser Type | MAX / Raycus |

| 4 | Central wavelength | 1064nm |

| 5 | Line length | 10 M |

| 6 | Cleaning efficiency | 12 m3/h |

| 7 | Support language | English, Chinese, Japanese, Korean, Russian, Spanish |

| 8 | Cooling Type | Water cooling |

| 9 | Average Power (W), Max | 1000W / 1500W/ 2000W / 3000W |

| 10 |

Average Power (W), Output Range(If adjustable)

|

0-100 |

| 11 | Pulse-Frequency (KHz),Range | 20-200 |

| 12 | Scanning Width (mm) |

10-150/300

|

| 13 | Expected Focal Distance(mm) | 160mm |

| 14 | Input Power | 380V/220V, 50/60H |

| 15 | Dimensions | 1100mm×700mm×1150mm |

| 16 | Weight | 200KG |