PriceList for 1.5kw Laser Welding Machine - Three Used Handheld Fiber Laser Cutting Welding Cleaning Machine – Knoppo Detail:

Application

Applicable Materials Of KC-M Handheld Fiber Laser Machine

Cutting Welding on stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate, metal pipe and tube, etc. Cleaning rust ,paint , powder coating and oil etc on metal .

Applicable Industries Of KC-M Handheld Fiber Laser Machine

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and metal mould etc.

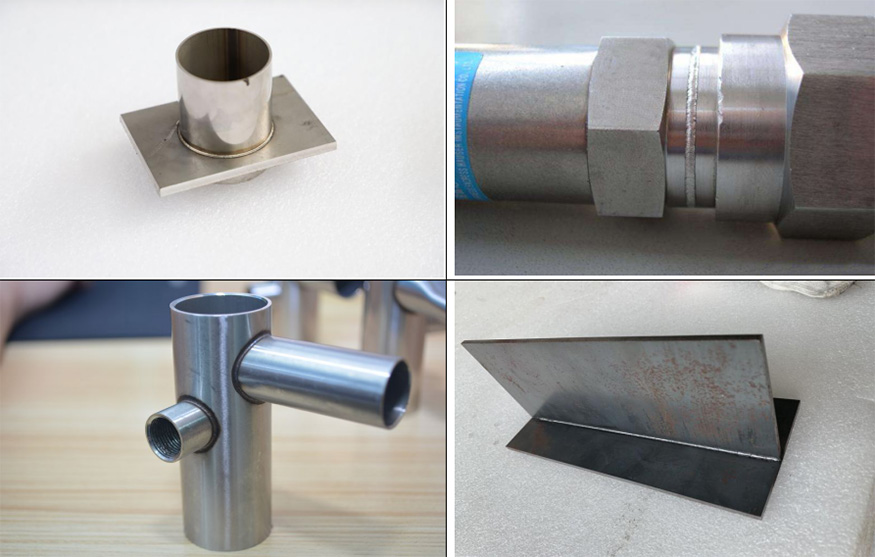

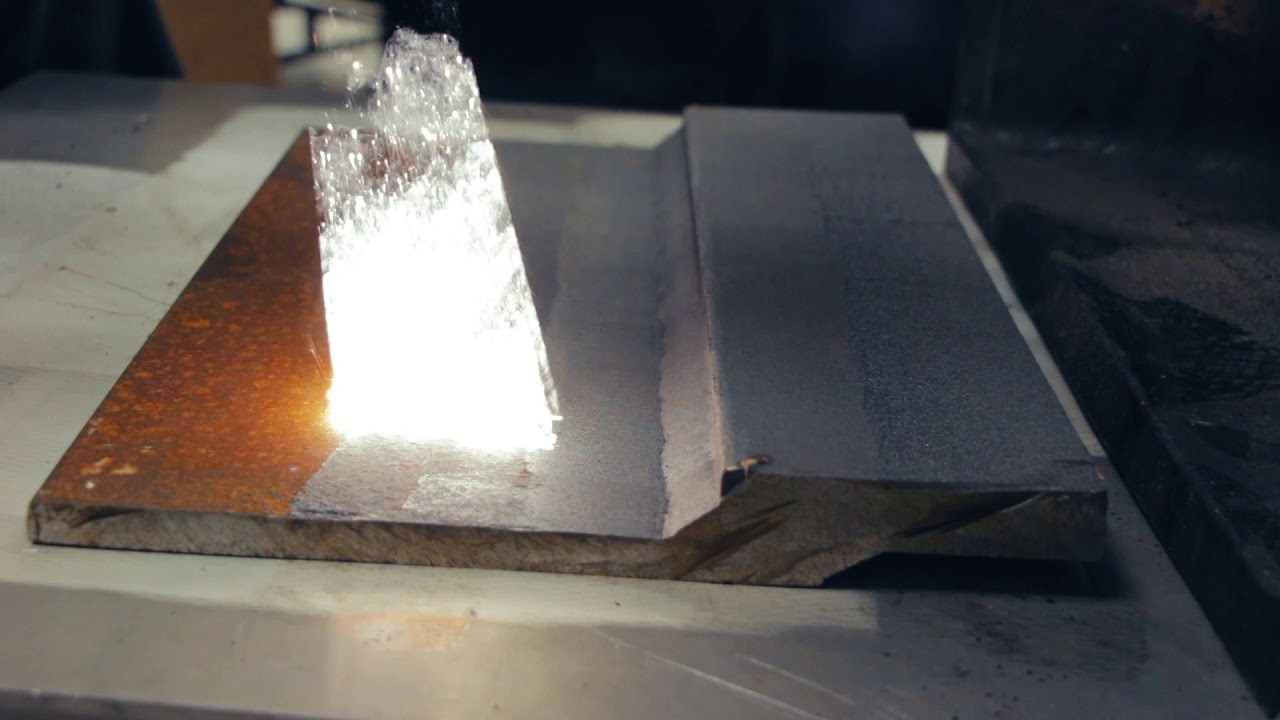

Sample

Welding

Cleaning

Configuration

Raycus Laser Source

It has the advantages of high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life, and maintenance-free operation. It can be widely used in welding, precision cutting, surface treatment, and other fields. Its optical fiber output characteristics make it easier to integrate with robots into flexible manufacturing equipment to meet the needs of three-dimensional processing.

S&A Water Chiller

S&A water chiller is a rack mount cooler designed for cooling up to 2KW handheld laser welding machine and mountable in a 19-inch rack. Because of the rack mount design, this industrial water cooling system allows stacking of related device, indicating a high level of flexibility and mobility. Temperature stability is ±0.5°C while the temperature control range is 5°C to 35°C. This circulating water chiller comes with a high performance pump. Water fill port and drain port are mounted on the front together with a thoughtful water level check.

Techinical parameters

|

Model |

KC-M |

|

Wavelength |

1070nm |

|

Max Welding Thickness |

8mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W |

|

Max Cleaning Width |

80mm |

|

Fiber Cable |

10m |

|

Support language |

Chinese , English , Russian And Korean |

|

Total Power Consumption |

8KW |

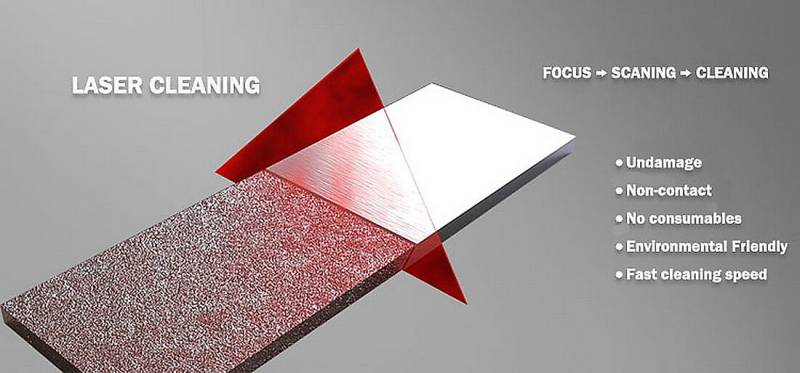

Advantages

- Safe removal of hazardous coatings & contaminants

- Eliminates need for grinding/sanding/grit blasting

- Won’t damage sensitive parts or historic surfaces

- Free of solvents, chemicals, abrasives, water, dust & noise

- Creates oxide-free metal surfaces

- Environment-friendly

How To Use Knoppo Fiber Laser Welding Cleaning Machine ?

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for PriceList for 1.5kw Laser Welding Machine - Three Used Handheld Fiber Laser Cutting Welding Cleaning Machine – Knoppo, The product will supply to all over the world, such as: Cancun, Miami, Argentina, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

2020 High quality Cnc Laser Cutting Machine - ...

-

Good Wholesale Vendors 3000w Laser Cutter - KF...

-

China Manufacturer for Steel Channels Plamsa Cu...

-

Factory Supply China Fiber Laser Cutting - 1kw...

-

Hot sale Reci Laser Engraving Machine - Small ...

-

2020 New Style 6000 Watt Fiber Laser Cutting Ma...