OEM/ODM Manufacturer Mdf Laser Cutter - Full Closed Fiber Laser Cutting Machine For Stainless Steel – Knoppo Detail:

Application

Applicable Materials Of Fiber Laser Cutting Machine

Fiber laser cutting machine can cut stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate, metal pipe and tube, etc.

Applicable Industries Of Fiber Laser Cutting Machine

Fiber laser cutting machine can be used for many industry. For example , machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Sample

Configuration

Double Fast Exchange Tables

The metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life.

Higher Safety Level

The all-around protective covering isolates laser radiation and pollution, offering higher safety level. Smoke and dust produced during cutting will be automatically collected to ensure a clean operating area, suitable for European CE standard. Smart monitoring system helps reduce accident rate.

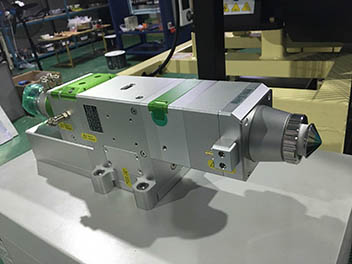

Switzerland Raytools Laser Head

This laser head is applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal. Increasing perforation focus length, separately setting perforation focal length and cutting focal length, improve cutting accuracy.

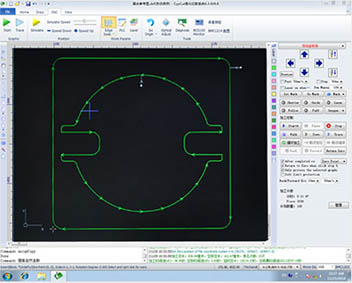

CYPCUT Control System

CYPCUT Control system of our fiber laser cutting machine can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhancing the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

BCS100 Capacitive Height Controller

BCS100 capacitive height controller (hereinafter referred to as BCS100) our fiber laser cutting machine is a high-performance control device which usedclosed-loop control method. BCS100 also provides a unique Ethernet communication (TCP / IP protocol) interface, it can easily achieve many functions with CypCut software, such as automatic tracking of height, segmented piercing, progressive piercing, edge seek, leapfrog, arbitrary setting of lift-up height of cutting head.Its response rate is also improved greatly. Especially in servo control aspects, its running speed and accuracy should obviously be better than other similar products, owing to dual closed-loop algorithm of speed and position. Support alarm while hitting the board and beyond the edge. Support edge detection and automatic inspection.

Techinical parameters

|

Machine Model |

KP Series |

|

Wavelength |

1070nm |

|

Cutting Area |

3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W / 12KW / 15KW / 20KW / 30KW |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Cutting parameters

| Cutting Parameters | 1000W | 1500W | 2000W | 3000W | 4000W | |

| Material | Thickness | speed m/min | speed m/min | speed m/min | speed m/min | speed m/min |

| Carbon steel( Mild Steel ) | 1 | 8.0–10 | 15–26 | 24–32 | 30–40 | 33–43 |

| 2 | 4.0–6.5 | 4.5–6.5 | 4.7–6.5 | 4.8–7.5 | 15–25 | |

| 3 | 2.4–3.0 | 2.6–4.0 | 3.0–4.8 | 3.3–5.0 | 7.0–12 | |

| 4 | 2.0–2.4 | 2.5–3.0 | 2.8–3.5 | 3.0–4.2 | 3.0–4.0 | |

| 5 | 1.5–2.0 | 2.0–2.5 | 2.2–3.0 | 2.6–3.5 | 2.7–3.6 | |

| 6 | 1.4–1.6 | 1.6–2.2 | 1.8–2.6 | 2.3–3.2 | 2.5–3.4 | |

| 8 | 0.8–1.2 | 1.0–1.4 | 1.2–1.8 | 1.8–2.6 | 2.0–3.0 | |

| 10 | 0.6–1.0 | 0.8–1.1 | 1.1–1.3 | 1.2–2.0 | 1.5–2.4 | |

| 12 | 0.5–0.8 | 0.7–1.0 | 0.9–1.2 | 1.0–1.6 | 1.2–1.8 | |

| 14 | 0.5–0.7 | 0.8–1.0 | 0.9–1.4 | 0.9–1.2 | ||

| 16 | 0.6-0.8 | 0.7–1.0 | 0.8–1.0 | |||

| 18 | 0.5–0.7 | 0.6–0.8 | 0.6–0.9 | |||

| 20 | 0.5–0.8 | 0.5–0.8 | ||||

| 22 | 0.3–0.7 | 0.4–0.8 | ||||

| Stainless steel ( Inox ) | 1 | 18–25 | 20–27 | 24–50 | 30–35 | 32–45 |

| 2 | 5–7.5 | 8.0–12 | 9.0–15 | 13–21 | 16–28 | |

| 3 | 1.8–2.5 | 3.0–5.0 | 4.8–7.5 | 6.0–10 | 7.0–15 | |

| 4 | 1.2–1.3 | 1.5–2.4 | 3.2–4.5 | 4.0–6.0 | 5.0–8.0 | |

| 5 | 0.6–0.7 | 0.7–1.3 | 2.0-2.8 | 3.0–5.0 | 3.5–5.0 | |

| 6 | 0.7–1.0 | 1.2-2.0 | 2.0–4.0 | 2.5–4.5 | ||

| 8 | 0.7-1.0 | 1.5–2.0 | 1.2–2.0 | |||

| 10 | 0.6–0.8 | 0.8–1.2 | ||||

| 12 | 0.4–0.6 | 0.5–0.8 | ||||

| 14 | 0.4–0.6 | |||||

| Aluminum | 1 | 6.0–10 | 10–20 | 20–30 | 25–38 | 35–45 |

| 2 | 2.8–3.6 | 5.0–7.0 | 10–15 | 10–18 | 13–24 | |

| 3 | 0.7–1.5 | 2.0–4.0 | 5.0–7.0 | 6.5–8.0 | 7.0–13 | |

| 4 | 1.0–1.5 | 3.5–5.0 | 3.5–5.0 | 4.0–5.5 | ||

| 5 | 0.7–1.0 | 1.8–2.5 | 2.5–3.5 | 3.0–4.5 | ||

| 6 | 1.0–1.5 | 1.5–2.5 | 2.0–3.5 | |||

| 8 | 0.6–0.8 | 0.7–1.0 | 0.9–1.6 | |||

| 10 | 0.4–0.7 | 0.6–1.2 | ||||

| 12 | 0.3-0.45 | 0.4–0.6 | ||||

| 16 | 0.3–0.4 | |||||

| Brass | 1 | 6.0–10 | 8.0–13 | 12–18 | 20–35 | 25–35 |

| 2 | 2.8–3.6 | 3.0–4.5 | 6.0–8.5 | 6.0–10 | 8.0–12 | |

| 3 | 0.5–1.0 | 1.5–2.5 | 2.5–4.0 | 4.0–6.0 | 5.0–8.0 | |

| 4 | 1.0–1.6 | 1.5–2.0 | 3.0-5.0 | 3.2–5.5 | ||

| 5 | 0.5–0.7 | 0.9–1.2 | 1.5–2.0 | 2.0–3.0 | ||

| 6 | 0.4–0.9 | 1.0–1.8 | 1.4–2.0 | |||

| 8 | 0.5–0.7 | 0.7–1.2 | ||||

| 10 | 0.2–0.5 | |||||

Video

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for OEM/ODM Manufacturer Mdf Laser Cutter - Full Closed Fiber Laser Cutting Machine For Stainless Steel – Knoppo, The product will supply to all over the world, such as: Argentina, Sacramento, Latvia, We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

-

OEM manufacturer Cnc Plasma Cutting Machinery -...

-

Good User Reputation for Laser Cut Machine - F...

-

OEM Factory for 1000w Laser Cutting Machine - ...

-

Professional China Nc Press Brake - WC67Y Meta...

-

factory customized 160a Plasma Cutter - Roboti...

-

Low MOQ for Tube Fiber Laser Cutting Machine -...