Recently , Knoppo RT400 H beam plasma cutting machine exported to The Dominican Republic successfully . This CNC H-Beam Cutting Coping Machine is widely used for steel structure,shipbuilding and gas&oil industries . It can cut H beam , I beam and channels etc . 6 axis servo control , 3 faces cutting is on one processing , and can cut any angle with 45 degree .

RT400 H beam cutting machine is also good configuration , 6 axis servo motor and driver is from Japan Fuji , Plasma generator is from China HUAYUAN 200A plasma , System is from Shanghai fangling . Most main parts is from famous brand , improve cutting precision and prolong working life .

1. About Cutting Efficiency Measurement

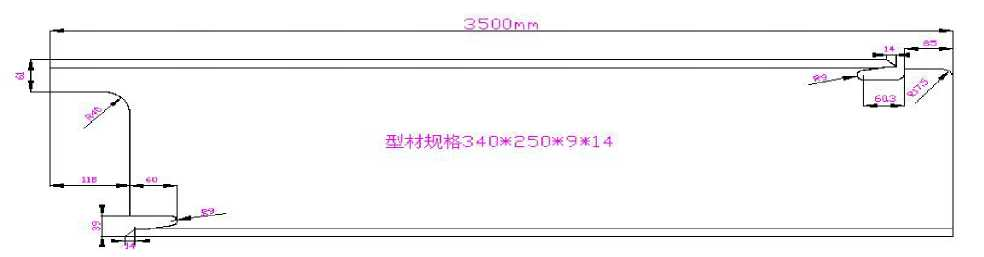

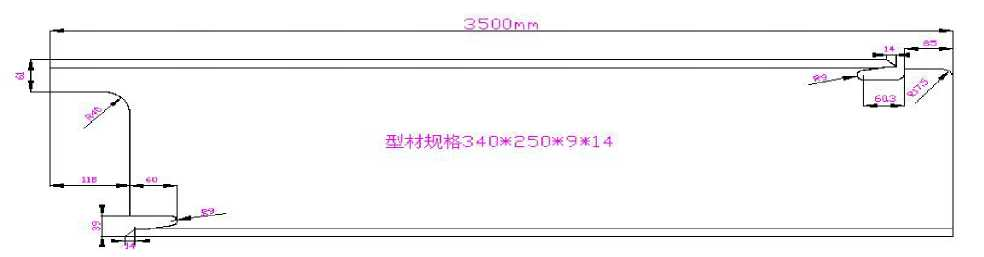

Profile specifications 340*250 as below drawing.( Max cutting length 3500mm. The main cutting process includes single and double-sided beveling, over-welded hole and web shaped track)

Adopt Huayuan fine plasma power source 200A current.

Provides stable source pressure and flow on site

Cutting result record:

Single structural profile cutting time is 8 minutes.

The distance between the two over-welded holes is 6-8 mm.

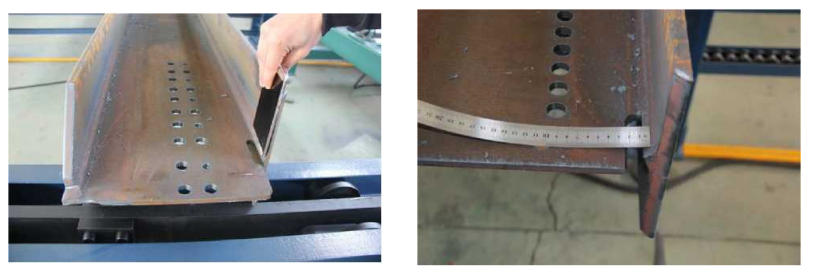

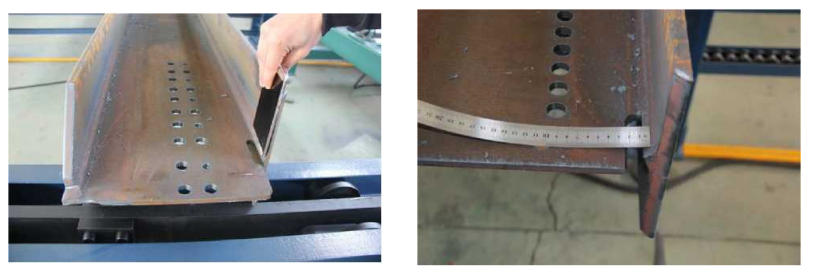

2. Real cutting performance

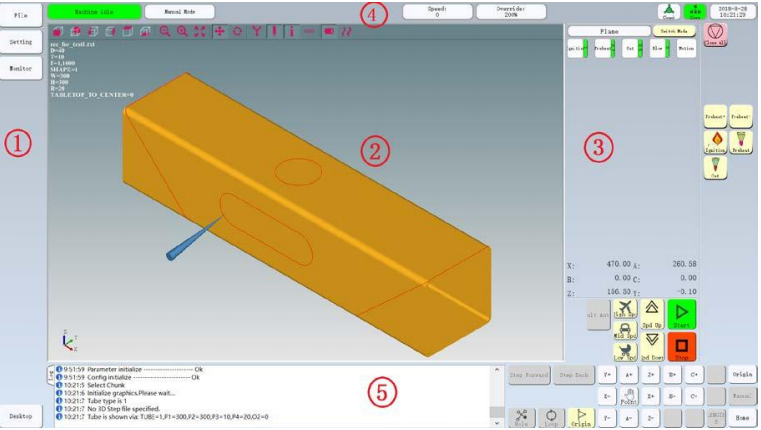

3. Fangling System Characteristic

Support Chinese and English two languages, and support other common

languages except Arabic.

Support for four bar linkage, fitting angle, infinite rotation, mechanical

arm (customized) and many other groove end mechanisms.

Chuck and friction disk support

Use open G code programming to support suffix TXT, CNC and other G

code formats.

Support EtherCAT protocol, which can drive EtherCAT bus servo.

Support for extensions of digital IO ports

Support the expansion of modules such as AD, DA and PWM.

Support soft limit function

Parametric and customized processing technology

Touch quick operation button to replace part of the electric button

Part of the interface control using QML plug-in programming, can be

customized locally

Support the automatic adjustment of cutting speed according to the

thickness of plate

Support automatic adjustment of cutting speed according to groove angle

Support plasma arc groove angle deviation correction

Supports single spindle maximum machining speed clamping

Support for M instruction extension, user can customize M instruction.

Support resistor, capacitor touch screen design

18.5-inch large operating interface design, state monitoring and

observation operation more convenient

3D Pipe View/Expand view two visualization modes3D view can rotate the translation operation, the user can observe the

cutting trajectory 360 degree beforehand

Machining track and workpiece magnification and reduction function

General input/output can be customized (constant open or closed),

customized name

Universal input port supports self-lock input definition

Support system one-key backup and restore functionality

All functions and processes of the system can be upgraded online,

eliminating the worry of after-sale

Support oxygen gas, plasma, demo, laser (need to customize) 4 kinds of

cutting mode

Customizable cutting mode

All kinds of processing parameters are complete, can meet the needs of

different processes

Support manual selection of perforation number

Real-time acceleration and deceleration in motion

A remote control that supports P2P mode and BCD (8421) mode

Support for Modbus HMI expansion

Log machine information output to facilitate maintenance analysis

4. Technical indicators of system

Control axle Number: Maximum up to 8 axis linkage

Control accuracy: ±0.001mm

Coordinate range: ± 99999.99mm

Maximum operating Speed: 30 m/min

Minimum Time class resolution: 1ms

System working power: DC +24V, Power greater than 150W

System working environment: temperature-10 ℃ to +60℃; relative

humidity 0-95% no condensation

General output: 16 Road, 200mA (scalable)

Knoppo Group is not only produce 6 axis H beam cutting machine , also 8 axis H beam cutting machine and 10 axis H beam cutting robot etc , we can meet all customer requirements . And we have also 17 years experience for laser machine , for example , fiber laser cutting machine , CO2 laser cutting engraving machine , laser marking machine , laser welding machine and laser cleaning machine etc , good quality and 3 years warranty .

Post time: Dec-09-2021