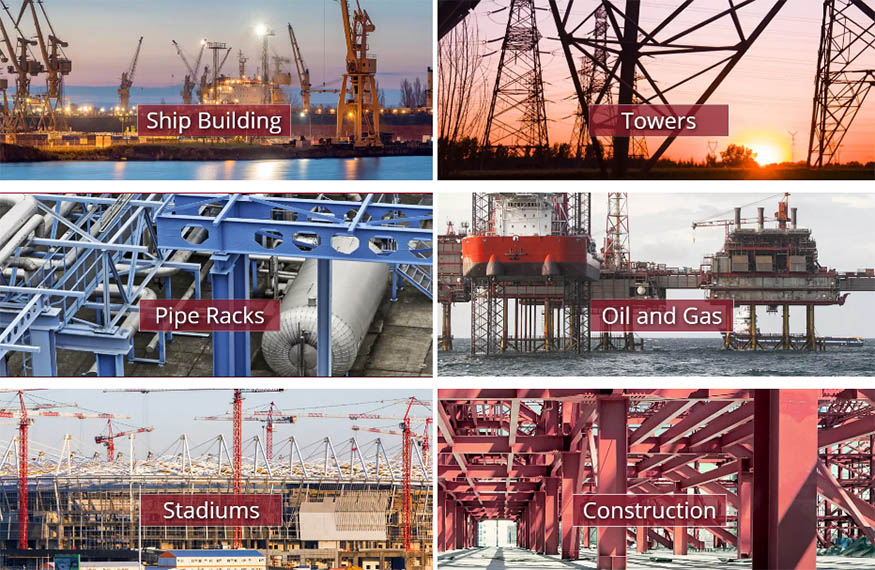

All laser cutting machine has their advantages , such as co2 laser , Yag laser etc, but it seems that the advantages of fiber laser cutting machine far exceed any other laser cutting machine . Fiber laser cutting has begun to receive more attention in the past few years. However, the fiber laser cutting machine’s benefits have brought multiple conveniences to metal working manufacturers across the world. With the rapid development of fiber laser cutting machine , it can easily and seamlessly adapt to a wide range of applications to different industries.

Fiber laser cutting machine has several advantages. Firstly, The fiber laser cutting machine can operate with high power and high efficiency and are suitable for many types of cutting procedures.

The fiber laser cutting machine is widely used in comprehensive processing in the sheet metal industry due to the advantages of excellent cutting effect, efficient cutting speed, low processing cost, and maintenance cost. It has become a piece of indispensable cutting equipment in sheet metal industry. The reasons why fiber laser cutting machines are popular in the sheet metal cutting machine market is mainly because of the following reasons.

High Flexibility

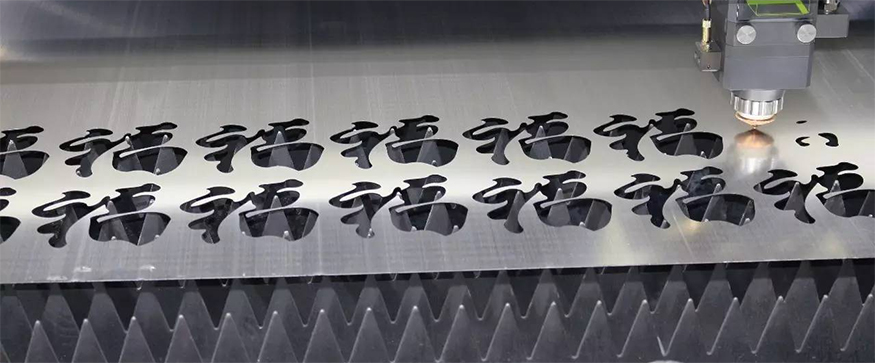

When processing thin metal sheets, the fiber laser cutting machine has high flexibility to realize flexible processing. It can process without subsequent secondary processing and is very suitable for massive production. The fiber sheet metal lase cutter’s working principle is to irradiate a laser beam with a high energy density to the sheet metal workpiece so that the part is heated and melted. And then use high-pressure gas to blow off the slag to complete the cutting, so there will be no burrs and repolishing conditions.

High Accuracy

The fiber laser cutting machine beam is concentrated in a small area with a diameter of about 0.1mm. The cutting is very precision and environmentally friendly as well.

The fiber laser cutting process adopts a fully automatic control system, which uses non-contact processing to ensure that the material is not damaged by mechanical pressure and will not damage the sheet metal pieces.

Economical

In the traditional cutting process, the cutting of sheet metal workpiece is basically done by blanking. When a new product or different shapes of sheet metal material is replaced, the mold needs to be changed, which invisibly increases the cost. What is more, it is not conducive to launching the product in time to form the competitiveness.

Nevertheless, the fiber laser cutting machine has a shorter cutting processing cycle. The cutting and processing of the pieces can be realized simply by imported into the equipment industrial control system through the drawing’s electronic version. In this case, the fiber laser cutting machine has greatly shortened the production cycle. For most of the company, shortening the production cycle means enhancing the competitiveness of the company. It is also conducive to cost control and can maximize economical value.

Fiber laser cutting machines play a key role on the sheet metal processing. And many sheet metal processing manufacturers will choose fiber laser cutting machines to cut sheet metal pieces instead of plasma or co2 laser cutting .

Among many metal laser cutting manufacturers, KNOPPO fiber laser cutting machine is popular on the market. Through years of development, KNOPPO has an annual production capacity of 3000 fiber laser cutting machines. The fiber laser cutting machine of KNOPPO are widely used in precision machinery, auto parts, kitchen and bathroom hardware, electronic and electrical, and many other industries.

Post time: May-21-2021