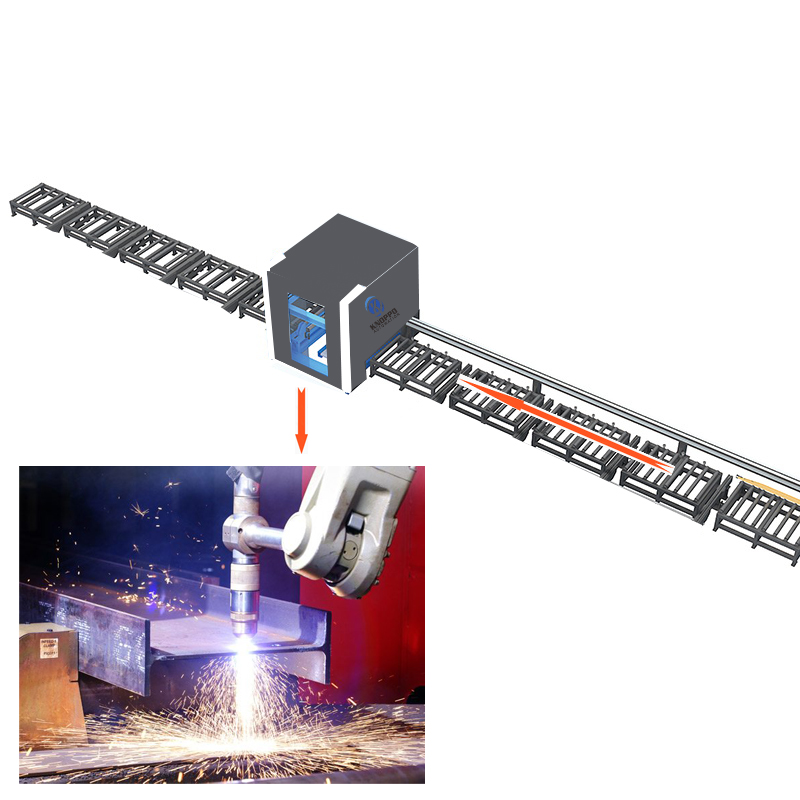

China Manufacturer for Steel Channels Plamsa Cutter - Automatic CNC H Beam Steel Plasma Cutting Robotic Machine – Knoppo Detail:

This H beam cutting machine is widely used in cutting and processing pipeline structural parts in construction, chemical, shipbuilding, mechanical engineering, metallurgy, electric power and other industries. In the past, most of this kind of processing used backward and complicated operation techniques such as making prototypes, scribing, manual lofting, manual cutting, and manual polishing. The CNC intersecting line cutting machine can cut and process such workpieces very conveniently. There is no need for the operator to calculate or program. You only need to enter the pipe radius, intersection angle and other parameters of the pipe intersecting system, and the machine can automatically cut the intersecting line of the pipe. Intersecting line holes and welding grooves. The CNC pipe intersecting line cutting machine adopts digital control, and the equipment [the number of control axes is two to six axes and other different models. Each model realizes the control axis interlocking during cutting such as working hours, and has the functions of cutting various intersecting lines and intersecting holes; fixed-angle bevel, fixed-point bevel, and variable-angle bevel cutting functions; pipe cutting compensation function

|

Working area |

Name |

Parameters |

| H beam/I beam/Channel Steel/Angle steel Beam | 600mm-1500mm | |

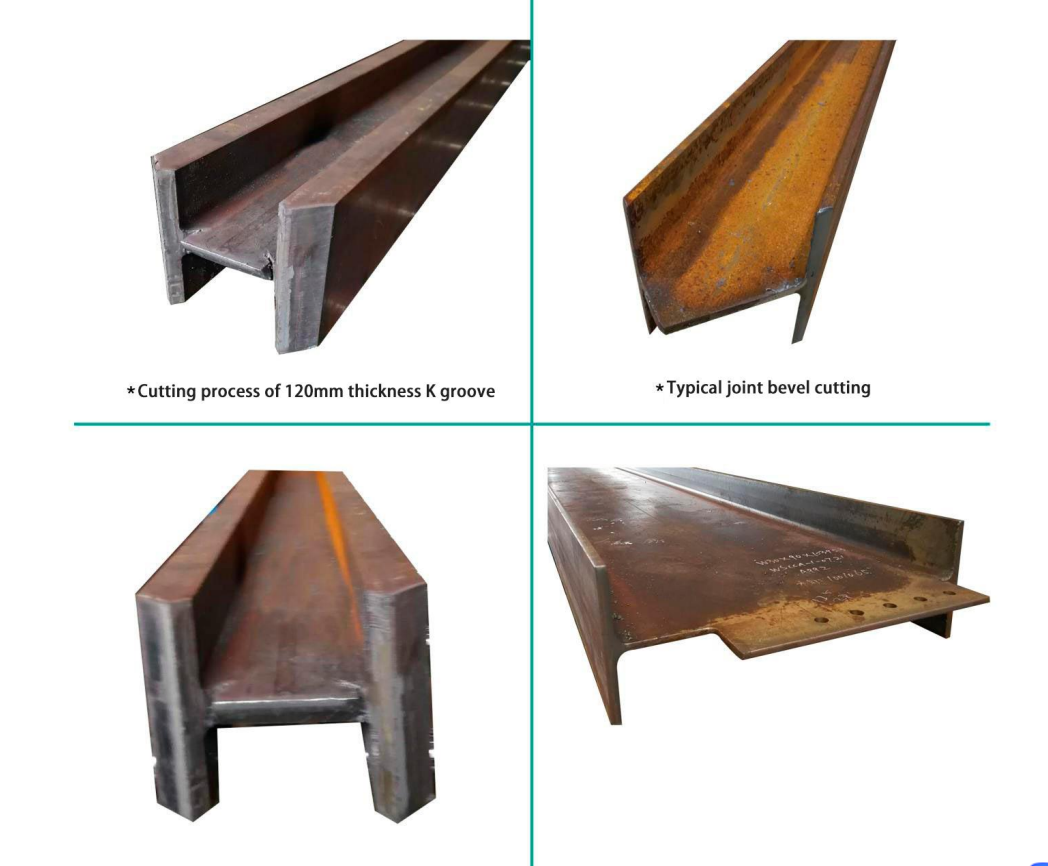

| Cutting method | Plasma/Flame | |

| Effective cutting length | 12m | |

| Profile cutting form | Fixed length straight cut, fixed length oblique cut | |

| Applicable materials | Carbon structural steel, stainless steel | |

|

Cutting |

Plasma power source | 200A |

|

method |

Plasma cutting thickness | Pierce cutting thickness 1-45mm |

| Oxy fuel cutting thickness | Vertical cutting thickness <60mm | |

| Beveling cutting | ±45。 | |

|

Machine accuracy |

Cutting precision in length | ±1.5mm |

| Cutting speed | 10 〜2000mm/min | |

| Moving speed | 10 〜6000 mm/min | |

|

Axis |

Robot axis | X Axis:the cutting torch movement left and right |

| Y1 Axis&Y2 Axis: True bilateral synchronization axis : the cutting torch movement forward and back | ||

| A Axis:the cutting torch rotation | ||

| B Axis:the cutting torch yawing | ||

| C Axis:the external workpiece is to the horizontal feeding | ||

| ZAxis:the cutting torch up and down | ||

|

Weight |

Maximum profile weight to be cut | 5000kg |

Video

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for China Manufacturer for Steel Channels Plamsa Cutter - Automatic CNC H Beam Steel Plasma Cutting Robotic Machine – Knoppo, The product will supply to all over the world, such as: Manchester, Bogota, Ecuador, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

OEM/ODM China Iron Cutting Machine Price - Ope...

-

Professional Design 80w Laser Cutter - Full Cl...

-

Ordinary Discount 4000w Fiber Laser Cutter - 1...

-

Factory Price For 120w Fiber Laser Marking Mach...

-

High Quality Laser Marker - KML-FT Metal Fiber...

-

Best Price for Wood Co2 Laser Marker - KML-UT ...