Affecting Factors Of the Cutting Quality Of Fiber Laser Cutting Machine

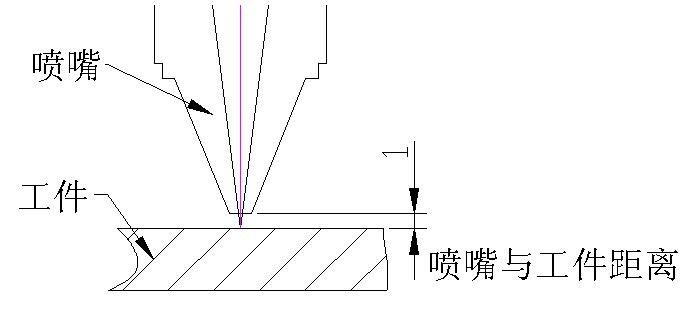

1. Cutting Height

As shown in the figure below, if the distance between the nozzle and the workpiece is too short, it may cause the collision of the plate and the nozzle; if the distance is too long, it may cause gas diffusion, causing more residues on the cutting bottom.

The distance between the nozzle and the workpiece can be set at the “Technology” interface, and the recommended distance is between 0.5-1.5mm.

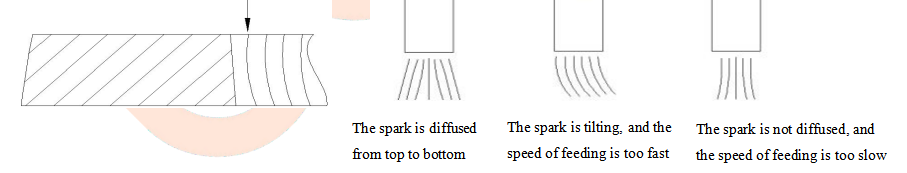

2. Cutting Speed

The speed of feeding can be judged from the cutting spark. Under the condition of normal cutting, the spark is diffused from top to bottom, and when the spark is tilted, the speed of feeding is too fast; if the spark is not diffused but condensed, the speed of feeding is too slow. The following figure shows the appropriate cutting speed, the cutting surface shows a smooth line, and no slag comes from the lower part.

In case of poor quality of cutting, it is recommended to carry out a general inspection first, of which the content and sequence are as follows:

1)Cutting height (it is recommended that the actual cutting height is between 0.5 and 1.5mm): If the actual cutting height is not accurate, the calibration should be carried out.

2)Nozzle: Check the type and size of the nozzle to see if it is used correctly. If it is correct, check whether the nozzle is damaged, and the roundness is normal.

3)It is recommended to conduct an optical center inspection of the nozzle with a diameter of 1.0, and the focus should be between -1 to 1 while inspecting the optical center. In this way, small light points are easy to be observed.

4)Protective lens: Check whether the lens is clean, and confirm there are no water, no oil and no slag on the lens.

Sometimes the protective lens may be fogged due to weather or too cold auxiliary gas.

5)Check whether the focus is set correctly.

6)Modify the cutting parameters.

After checking the above six items, if no problems, modify the parameters according to the phenomenon.

| Metal burrs at the bottom surface are difficult to remove. | The cutting speed is too highAir pressure is too low

Gas is not pure The focus is too high |

Reduce the cutting speedIncrease air pressure

Use pure gas Lower the focus |

| Burrs are only on one side. |

Coaxial laser is not correct.The opening of the nozzle has defects. | Align coaxial laser

Replace the nozzle |

| Materials are discharged from above. |

Power is too low The cutting speed is too high |

Increase the power Reduce the cutting speed |

| The surface of cutting is not precise.

|

Air pressure is too highThe nozzle is damaged.

The nozzle diameter is too large. |

Reduce air pressure

Replace the nozzle Install an appropriate nozzle |

|

Stainless steel: Cutting with N2 high pressure. |

||

|

Defects |

Possible Cause |

Solutions |

| Regular small droplet-like burrs are produced |

The focus is too low

The cutting speed is too high |

Raise the focus

Reduce the cutting speed |

| Irregular long filamentous burrs are produced on both sides, and the surface of large plate discolors. |

The cutting speed is too lowThe focus is too high

Air pressure is too low

The material is too hot |

Increase the cutting speedLower the focus

Increase air pressure

Cool the material |

| Irregular long burrs are produced on the cutting edge. | Coaxial laser is not correct.The focus is too high

Air pressure is too low

The cutting speed is too low |

Align coaxial LaserLower the focus

Increase air pressure Increase the cutting speed |

| The cutting edge becomes yellow |

Nitrogen contains oxygen impurities. |

Use high-quality nitrogen |

|

Light beam is diffused at the beginning. |

The acceleration is too high The focus is too lowThe molten material cannot be

discharged |

Reduce the acceleration

Raise the focus Pass through a circular hole |

|

The kerf is rough |

The nozzle is damaged. The lens is dirty | Replace the nozzleClean the lens, and replace it if necessary. |

| The material is discharged from above. |

The power is too low

The cutting speed is too fast Air pressure is too high |

Increase the power

Reduce the cutting speed Reduce air pressure |

Post time: Mar-01-2021