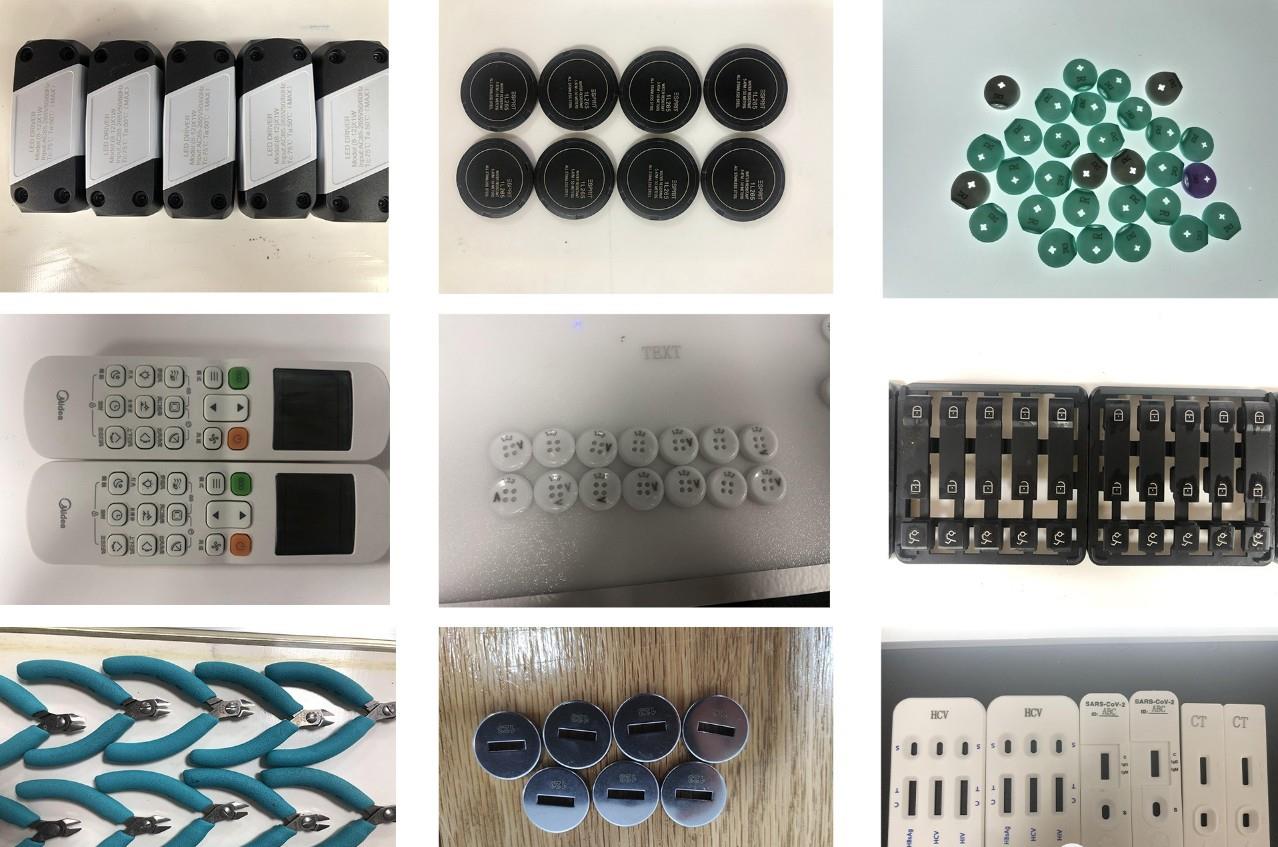

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

1. The pieces are very small, and the fixtures are manually used for positioning, which is difficult to place, slow and takes a long time;

2. There are many types of products, and many sets of fixtures are required to match, and the cost is high;

3. Manual placement requires and manual confirmation of the marking position, low efficiency and high labor cost;

4. Manual marking, there is a phenomenon that the placement is not always in same place, resulting in a high waste rate;

5. One person can only operate one machine, mass production, and the efficiency is very low;

6. There may be mistakes in manual operation, resulting in missed typing or wrong content, etc., resulting in customer complaints.

In view of the various problems encountered in the above industrial production, Knoppo visual positioning laser marking machine has its obvious advantages:

1. Need not fixtures, and it can be placed flatly at will to accurately locate;

2. Add product templates in minutes, no need to worry about the variety of products, and it is convenient to adjust the machine;

3. The marking products can be placed at will, saving customers the cost of positioning the mold and the cost of positioning time;

4. The intelligent visual positioning system automatically batch processing, and the production capacity is increased by 3 to 10 times;

5. The vision software algorithm automatically calculates the operating conditions at high speed, without human operation errors;

6. A single person can operate multiple devices at the same time, greatly improving the efficiency;

7. It can be matched with mechanical platforms such as assembly line, X/Y platform, and multi-station to realize automatic laser marking;

Post time: Aug-16-2022