I. Maintenance Overview

1.1 List of Main Maintenance

| Period/RunningHours | Maintenance Part | Maintenance Work |

| 8h | Removal of slags and dust on the X-axisdustproof cloth | Check and clean up dust and slag on theX-axis dustproof cloth. |

| 8h | Slags and dust collection containers -scrap vehicle | Check and clean up slags and dustcollection containers – scrap vehicle. |

| 8h | Removal of slags and dust on the X-axisprotection plate | Clean up slags and dust on the X-axisprotection plate. |

| 40h | Inspection of the pneumatic componentsand pipelines of the pneumatic system | Check the pneumatic components,pipelines, etc of the pneumatic system |

| 40h | Inspection of the gas circuit componentsand pipeline of the gas source | Check gas circuit components, pipeline, etc.of the gas source |

| 40h | Inspection of the circulating waterpipeline | Check the circulating water pipeline, etc. |

| 100h | Refueling and cleaning of the self-lubricating container | Check whether to timely refuel theself-lubricating container, and check and clean up oil circuit. |

| 500h | Cleaning of slags and dust in the centralsquare tube | Check and clean up slags and dust in the airvent. |

| 500h | Cleaning of filter screen of thewater-cooling machine | Clean up filter screen of the water-coolingmachine. |

| 1000h | Oil change and cleaning of theself-lubricating container | Rinse thoroughly the self-lubricatingcontainer, and replace lubricant. |

| 2000h | Cleaning and lubrication of Z-axis guide rail and ball screw, as well as cleaningand grease-injection of Z-axis guide slide block | Check and clean up Z-axis guide rail, guide slide block and ball screw; add lubricatinggrease to Z-axis guide slide block; and lubricate ball screw. |

| 2000h | Cleaning and lubrication of X, Y-axisguide rail and X, Y-axis gear rack | Check and clean up X, Y-axis guide rail, andclean up and lubricate X, Y-axis gear rack. |

| 5000h | Adjustment of X,Y axis gear rack back lash | Check and verify the verticality of X,Y-axis, and respectively check, verify and adjust X,Y-axis gear rack back lash. |

| Every six months | Cooling device | Replace cooling water (clean circulatingwater). |

1.1 Lubrication

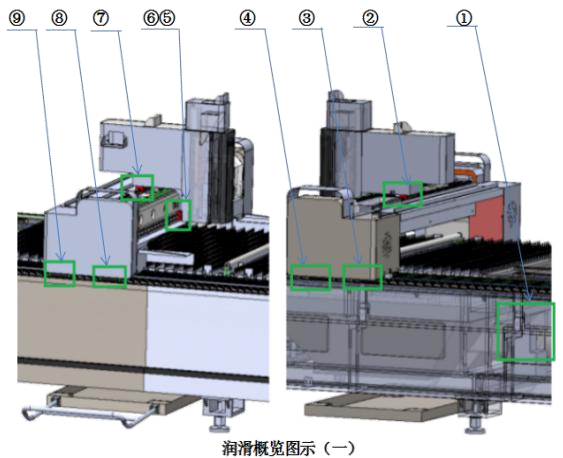

Sketch of lubrication overview (i)

1 Self-lubrication pump ② Y-axis upside guide slide block 1 ③ X-axis right side guide slide block 1

④ X-axis right side guide slide block 2 ⑤ Y-axis downside guide slide block 1

⑥ Y-axis downside guide slide block 2 ⑦ Y-axis upside guide slide block 2

⑧ X-axis left side guide slide block 2 ⑨X-axis left side guide slide block 1

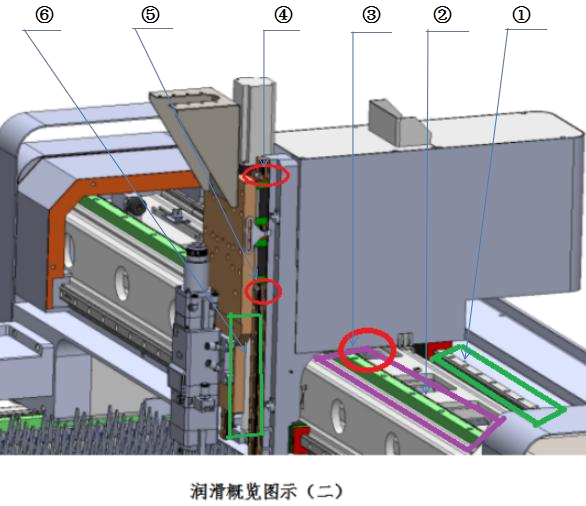

① Y-axis guide rail ② Y-axis gear ③ Y-axis gear rack back lash

④ Z-axis upside guide slide block ⑤ Z-axis downside guide slide block ⑥ Z-axis ball screw

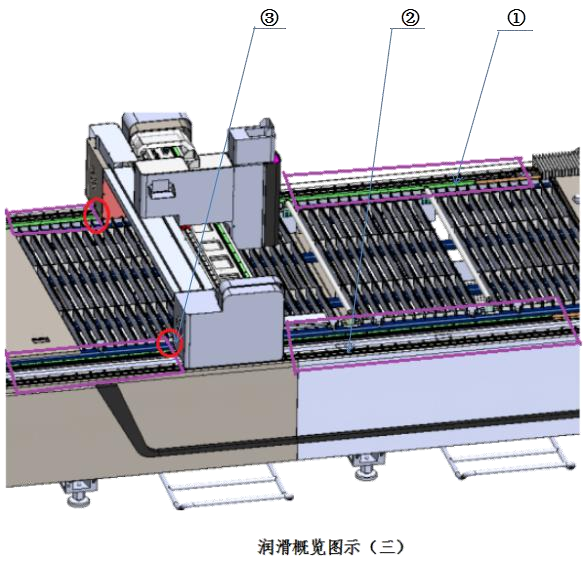

① X-axis rack ② X-axis guide rail ③ X-axis gear rack back lash

Post time: Feb-22-2021